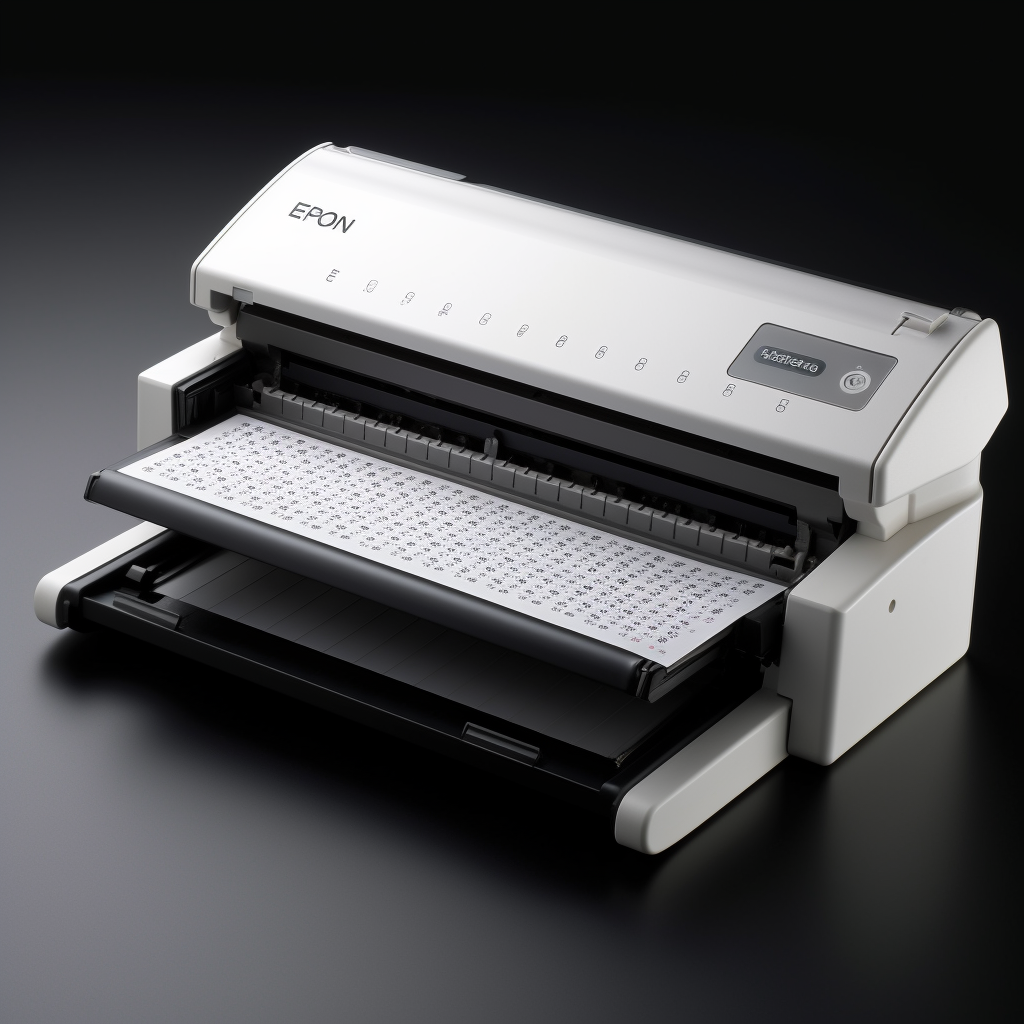

To achieve optimal print results with a dot matrix printer, here are some key points regarding paper and the paper feeding mechanism:

- Paper Type: Select paper specifically designed for dot matrix printers, such as continuous paper or multipart forms. These papers are specially designed to work well with the feeding and printing mechanism of dot matrix printers.

- Paper Quality: Choose high-quality paper to enhance print results. Opt for paper with appropriate thickness and smoothness to ensure even printing and prevent ink bleed.

- Paper Size: Use paper that is compatible with the dot matrix printer and ensure proper alignment for smooth paper feeding. Mismatched paper sizes may cause feeding issues or poor print results.

- Paper Weight: Select an appropriate paper weight to ensure the paper remains flat during the printing process. Too light of a paper weight may cause curling, while too heavy of a weight may increase wear on the print head and impact print quality.

- Paper Feeding Mechanism: Ensure the paper feeding mechanism of the dot matrix printer is functioning properly, allowing the paper to feed smoothly into the printing area. Check the feed rollers and paper sensors, keeping them clean and in good working condition.

- Print Gap: Adjust the print gap between the print head and the paper based on the paper thickness. A gap that is too small may cause ink bleed, while a gap that is too large can impact print quality and clarity.

In summary, selecting specialized paper designed for dot matrix printers with good quality and flatness, ensuring proper paper alignment and smooth paper feeding, can maximize print quality with a dot matrix printer. Additionally, making appropriate adjustments and performing maintenance tasks like adjusting paper thickness settings and cleaning the print head can further optimize print results.